Global Directory

- Anguilla - English

- Antigua & Barbuda - English

- Aruba - English

- Bahamas - English

- Barbados - English

- British Virgin Islands - English

- Cayman - Islands - English

- Curacao - English

- Dominica - English

- Dominican Republic - Español

- Grenada - English

- Guadeloupe - English

- Haiti - English

- Jamaica - English

- Martinique - English

- Puerto Rico - English

- Puerto Rico - Español

- Saint Barthélemy - English

- Saint Kitts and Nevis - English

- Saint Lucia - English

- Saint Martin - English

- Saint Vincent & The Grenadines - English

- Trinidad & Tobago - English

- Virgin Islands - English

- Austria - Deutsch

- Belgium - Français

- Belgium - Nederlands

- Bosnia & Herzegovina - English*

- Bulgaria - English*

- Croatia - English*

- Czech Republic - Čeština

- Denmark - Dansk

- Finland - Suomeksi

- France - Français

- Germany - Deutsch

- Greece - English

- Hungary - Magyarország

- Ireland - English

- Italy - Italiano

- Macedonia - English

- Netherlands - Dutch

- Norway - Norge

- Poland - Polski

- Portugal - Português*

- Romania - Romanian

- Russia - Русский

- Serbia - English

- Slovakia - Slovenčina

- Spain - Espanol

- Sweden - Swedish

- Switzerland - Deutsch*

- Switzerland - Français*

- Switzerland - Italiano*

- United Kingdom - English

-

Products and Solutions

-

Services and Support

- Operations Maintenance and Repair Services

- Product Documentation

- Product Selection Tools

- Energy and Efficiency Solutions

- Design and Construction Solutions

- Optimization and Retrofit Solutions

- Systems Integration

- Managed Services

- Fire Maintenance and Support

- Security Maintenance and Support

- Replacement Parts and Supplies

Predictive and Diagnostic Service Powered by OpenBlue, Catch Building Equipment Problems Before They Happen

Learn more -

Industries

- Insights

-

About Us

Global Directory

- Anguilla - English

- Antigua & Barbuda - English

- Aruba - English

- Bahamas - English

- Barbados - English

- British Virgin Islands - English

- Cayman - Islands - English

- Curacao - English

- Dominica - English

- Dominican Republic - Español

- Grenada - English

- Guadeloupe - English

- Haiti - English

- Jamaica - English

- Martinique - English

- Puerto Rico - English

- Puerto Rico - Español

- Saint Barthélemy - English

- Saint Kitts and Nevis - English

- Saint Lucia - English

- Saint Martin - English

- Saint Vincent & The Grenadines - English

- Trinidad & Tobago - English

- Virgin Islands - English

- Austria - Deutsch

- Belgium - Français

- Belgium - Nederlands

- Bosnia & Herzegovina - English*

- Bulgaria - English*

- Croatia - English*

- Czech Republic - Čeština

- Denmark - Dansk

- Finland - Suomeksi

- France - Français

- Germany - Deutsch

- Greece - English

- Hungary - Magyarország

- Ireland - English

- Italy - Italiano

- Macedonia - English

- Netherlands - Dutch

- Norway - Norge

- Poland - Polski

- Portugal - Português*

- Romania - Romanian

- Russia - Русский

- Serbia - English

- Slovakia - Slovenčina

- Spain - Espanol

- Sweden - Swedish

- Switzerland - Deutsch*

- Switzerland - Français*

- Switzerland - Italiano*

- United Kingdom - English

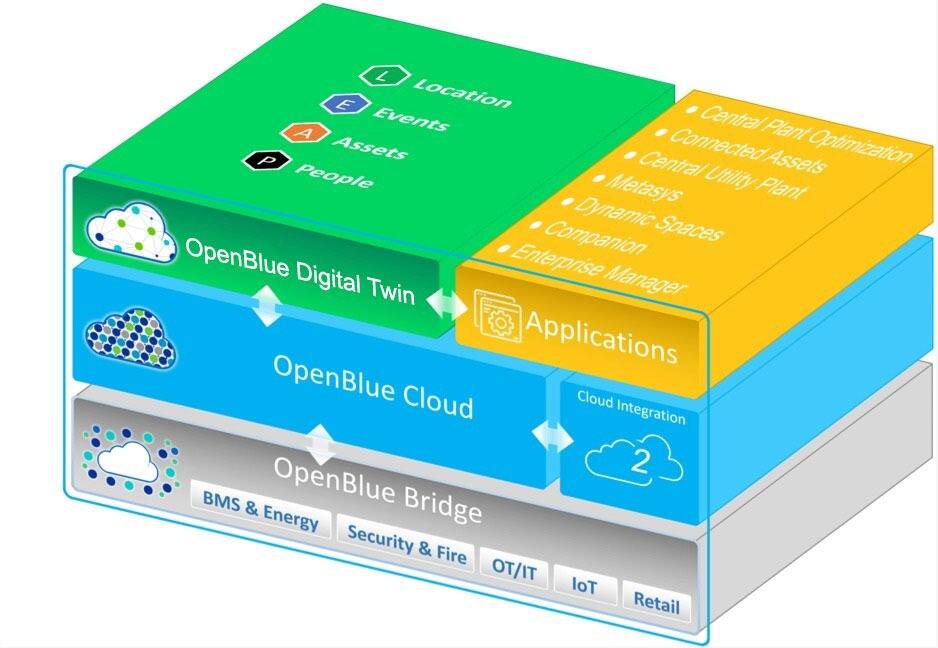

OpenBlue Digital Twin

The Foundation for the Blueprint of the FutureOpenBlue Digital Twin: Designed for Buildings. Infused with AI.

Johnson Controls is putting your people, spaces and assets at the heart of safety, security and sustainability. With over a century of building experience, we are helping people imagine and anticipate unlimited outcomes by leveraging digital twin technology to improve the way we can plan and respond to events in real time.

OpenBlue Digital Twin Overview

OpenBlue Digital Twin is a managed service for the enablement and mapping of smart buildings by creating a digital replica of assets, processes, people, places, systems and devices. While harmonization and the linking of data is its primary use, twins are brought to life by creating a replica environment by leveraging data in and around the building. The buildings' digital twin includes the building structure, location, assets, people, as well as the past, present and future events related to the building and the environment.

OpenBlue Digital Twin

Locations, Events, Assets and People come together with Johnson Control's Digital Twin as the Al-infused foundation to intelligent buildings.

3D BIM

Digital Twin Visualization

Digital Twinning is integrated into the 3D BIM for contextual visualization, enabling an immersive analysis of your locations, events, assets and people in the context of the physical building.Applications for OpenBlue Digital Twin in the built environment

Prediction: Digital twins bring together all of the data necessary for predictive algorithms and artificial intelligence systems, from fault predictions on equipment to building utilization and optimization.

Operations: A digital twin of a building gives building managers and occupants a real-time view of the integrated systems of the building.

Cost reduction: Digital twins help buildings operate more efficiently by helping predict and avoid unexpected costs, identify system inefficiencies, and better estimate when replacement parts are needed.

Understanding System Interactions: Digital twins from multiple systems and objects can be combined to better understand how they will interact with each other. This is particularly helpful when systems and products come from different suppliers.

Security: Digital twins provide a real-time view of the building and its occupants while incorporating historic trend data. The digital twin can be used to highlight “abnormal” actions or events that could portend security issues.

OpenBlue Bridge is the live connection between the physical and digital replicas, enabling data exchange for seamless communication and action.

Reach out to us below to learn how OpenBlue can power your mission.

- Operations Maintenance and Repair Services

- Product Documentation

- Product Selection Tools

- Energy and Efficiency Solutions

- Design and Construction Solutions

- Optimization and Retrofit Solutions

- Systems Integration

- Managed Services

- Fire Maintenance and Support

- Security Maintenance and Support

- Replacement Parts and Supplies

- Operations Maintenance and Repair Services

- Product Documentation

- Product Selection Tools

- Energy and Efficiency Solutions

- Design and Construction Solutions

- Optimization and Retrofit Solutions

- Systems Integration

- Managed Services

- Fire Maintenance and Support

- Security Maintenance and Support

- Replacement Parts and Supplies